- Markets

- Catalog

- Services & Solutions

- Newsroom

- Documents

- About Nexans

-

Nexans Insights

- Nexans Insights

-

Blog Posts

- Overview

- The path to effective fire safety in buildings

- Big data & AI

- Electrical and Fire Safety

- IoT

- Unveiling innovations transforming the industry

- Transforming buildings industry with 3D printing and modular construction

- Powering the digital change

- Unleashing the power of DC buildings

- Sustainable buildings for a brighter future

- Industry 1, 2, 3, 4... and 5.0

- Nexans copper odyssey

- Localizador de tiendas

- Search

- Contact us

- Compare

- Sign in

Nexans SHD-GC-EU (CSA)

Nexans SHD-GC-EU (CSA)

Portable cable used for the utilization of electrical energy in surface and underground mines and similar applications.

EPR/TPU. 90°C. 2 kV - 5 kV - 8 kV - 15 kV - 25 kV Read moreDescription

Description

Standards

-

ProductCSA C22.2 No. 96-17; ICEA S-75-381

Applications

Extra-heavy-duty trailing cable designed for used in mining machines, dredges, sholves, and similar mobile equipment, also suitable to be used with stationary equipment or medium voltage distribution in mines where higher flexibility is desired.

Construction: Multiconductor with three individually shielded power conductors, two grounding conductors, and one ground-check conductor.

1. Conductor: Very flexible stranded copper conductors.

2. Conductor shield: Conducting stress control material.

3. Insulation: Ethylene Propylene Rubber (EPR).

4. Insulation shield: Conducting material.

5. Metallic shield: Composite tinned copper/fiber braid.

6. Grounding conductors: Two flexible stranded bare copper conductors. Sizes according to CSA C22.2 No. 96-17.

7. POWERMINE® Super Pilot: one highly flexible conductor, insulated with EPDM with excellent insulation resistance properties and highly reinforced thanks to the incorporation of aramid yarns in the conductor.

8. Reinforcement: Fabric tape and double synthetic servings applied over the cores asembly.

9. Jacket: Extra-heavy-duty Thermoplastic Polyurethane (TPU). Colour upon request. Jacket thickness according to Canadian Standard CSA C22.2 No. 96.17

Marking: NEXANS CHILE POWERMINE SHD-GC-EU "size" "voltage" "date"

Alternative with chlorinated polyethylene (CPE): POWERMINE® SHD-GC-CP

.

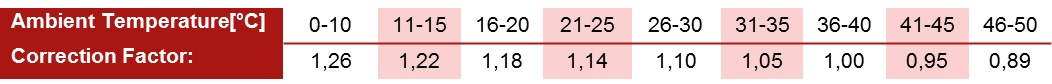

CURRENT CARRYNG CAPACITY FOR MINE TRAILING CABLES

The recommended ampacities are based on an ambiet temperature of 40°C (104°F) in air according to ICEA S-75-381, Annex H. Correction factors for ampacities at various ambient temperatures are as follows:

CURRENT CARRYNG CAPACITY FOR MINE TRAILING CABLES

NOTES

When the cables are used with one or more layers wound on a reel, the ampacities shal be corrected according to the amount of layers and reel type. For further details, see the technical guide: "Ampacity derating factors for mine trailing cables coiled on reels".

Values not defined as "maximum", "max.", "minimum" or "min." are not normative requirements in the standard and they are indicative only.

Characteristics

Characteristics

Construction characteristics

Construction characteristics

Mechanical characteristics

Mechanical characteristics

Usage characteristics

Usage characteristics

Resources

Resources

Documentation

Related products

Our websites

Select your country to find our products and solutions

-

Africa

- Africa

- Ghana

- Ivory Coast

- Morocco

- North West Africa

- Americas

- Asia

- Europe

- Oceania